Lubinpla AI

Autonomous Troubleshooting for Industrial Chemistry

By combining artificial intelligence, industrial engineering, chemical science, and applied research, we’re reshaping how solutions are conceived, engineered, and proven in the real world.

Industrial chemical decisions sit at the core of modern industry. In practice, that means selecting the right products, applying them under the right conditions, and resolving the technical issues that inevitably arise in real plants. Today, those decisions still rely on scattered expertise, incomplete documentation, and slow trial-and-error across thousands of possible products and process variables. The result is a process that is costly, hard to scale, and often too slow to keep up with the safety, productivity, and ESG demands industry is facing.

We believe there is a different way to do industrial chemistry

By building a closed-loop system around real field data, domain-specific knowledge, and AI agents specialized in industrial chemicals, Lubinpla focuses on one thing: helping you design and select the right product and solve technical problems with confidence. Our platform continuously ingests project records, work logs, test results, and confidential documents, then applies an AI engine that combines mechanistic reasoning with pattern-based learning to recommend products, explain root causes, and quantify risks and trade-offs. Every interaction feeds back into the system, so troubleshooting, product selection, and process optimization become faster, more reliable, and tightly aligned with the realities of your production environment and your business.

HOW IT WORKS

Pushing industrial chemistry into probative evidence

We combine analytical expertise, predictive models, real-world experiments, and closed-loop optimization to design and deploy better industrial chemical solutions fasters.

INTERPRET

We interpret your field data, lab reports, and work logs to build a coherent view of what is actually happening in your processes, turning scattered technical records into structured insights on any operating condition.

SIMULATE

From that understanding, we use AI models to simulate how different chemistries and settings behave before you touch the process, so you can concentrate trials on the few options with the highest impact.

OPTIMIZE

As real-world results come back, the platform uses a closed-loop cycle to refine formulations, dosages, and operating windows, aligning recommendations more and more with your cost, safety, and ESG targets.

AUTOMATE

Mature playbooks are delivered as autonomous assistants inside daily workflows, suggesting products, setpoints, and troubleshooting steps in real time so teams can act confidently without digging through documents or waiting for outside support.

Transforming every interaction into structured knowledge on the path to a new era of differentiated value

Mission Statement

Our mission is to accelerate smarter, more sustainable industrial operations by designing chemical solutions that reduce energy use and total cost of ownership across diverse environments. As your trusted agent, we empower professionals to unlock new solution and lead the shift to intelligent, sustainable industry with confident decisions at every stage.

PROJECT

Ensure operational transparency

Condition Management

Define and track process conditions in real time so the assistant delivers context-specific recommendations for each project.

Traceable Logs

Trace product name, quantity, application time, and operating conditions for each use to enable data-driven performance analysis across projects.

Actionable Insights

Extract actionable insights by combining technical knowledge with real-world data to clarify complex issues and accelerate decision-making.

NOTE

Leverage all of time and efforts

Process Journal

Document every operational step and field activity to support accurate reporting, diagnostics, and improvement tracking.

Quality Diagnosis

Accumulate structured logs that can be analyzed over time to reveal performance bottlenecks, frequent issues, unsafe patterns, and optimization opportunities within your chemical workflows.

Contextual Collaboration

Enable secure sharing of worklogs with relevant teams, along with real-time commenting and reply threads to support transparent, role-based collaboration on key operational data.

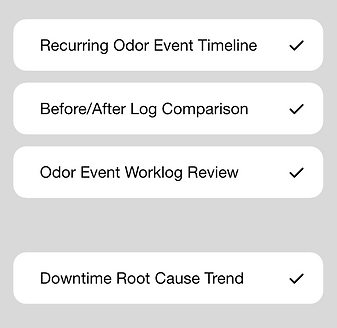

WORKFLOW

Pre-purpose templates

Automate the Routine

Replace repetitive manual tasks with automated workflows for reporting, compliance, and daily operations.

Scalable Efficiency

From small teams to enterprise operations, scale workflows effortlessly with AI-driven orchestration that adapts to your business needs.

Rapid Onboarding

Launch workflows in minutes with pre-built templates, and quickly move from setup to meaningful action with built-in dashboards and KPIs.

DEN

Enterprise-grade focused workspace

Real-Time Knowledge

Tap into your organization’s expertise instantly. No need for manual uploads or document hunts.

Scalable Analysis

Handle massive volumes of documents efficiently without slowing down performance or overloading shared systems.

Full Data Control

You own the workspace. no cross-data contamination, no external exposure. All uploads stay isolated and secure.

Enterprise-Grade

We never train on your data. Backed by industry-standard encryption and strict isolation.

Agentic Workflows

Generates expert-quality outputs for complex workflows — no extra prompting required.

High Expertise

Vertical AI for professionals solving complex, high-stakes problems with proprietary algorithms.

Universal Intelligence

From customer management to advanced analytics, we optimize your experience.

WHERE IT WORKS

Use Case

Materials Protection

Corrosion varies by humidity, heat cycles, micro-contaminants, and logistics.

Industrial Lubricants

Wear patterns shift with pressure spikes, surface chemistry, and new tooling speed.

Cleaning & MRO

Chemical regulation changes and complex substrates create unexpected cleaning failures.

Bonding

New materials demand new adhesion insights and failures often appear too late.